By Bob Wettermann

There are cases when you need to quickly repair a BGA or CSP or POP package location. In removing the device there may be times where you would like to reball it and place it back onto the same location. In those cases you may night have the time to wait those few days for a customized reballing preform to the fit the package exactly. In those cases the BEST BGA reballing kit is the right tool/kit to have in your tool box.

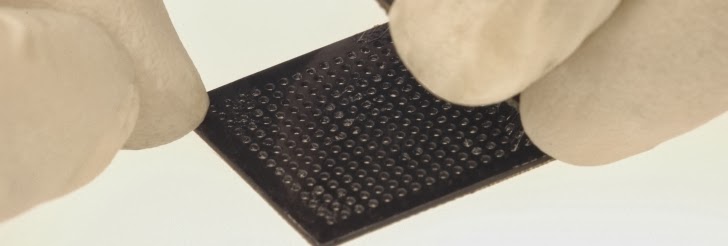

There are cases when you need to quickly repair a BGA or CSP or POP package location. In removing the device there may be times where you would like to reball it and place it back onto the same location. In those cases you may night have the time to wait those few days for a customized reballing preform to the fit the package exactly. In those cases the BEST BGA reballing kit is the right tool/kit to have in your tool box.

|

| BEST BGA Reballing Kit for Versatile Reballing Solution |

By using this kit and some ingenuity when it

comes to cutting, or some tape for blocking off or a few solder balls for

adding at certain location many different new patterns can be made. This kit

includes a variety of preforms at certain consistent patterns and pitches that

allows you to do this.

Follow These Steps to Reball your BGA:

1. Deball and Prep Site Location. After the device is removed the remnant solder needs to

removed. By using a soldering wick and hand soldering iron and some paste flux

the remnant solder can be removed.

Apply paste flux to the BGA requiring to be cleaning up

Apply paste flux to the BGA requiring to be cleaning up

.jpg)

Apply paste flux

Use Braid and Soldering Iron to Clean Up Site Locations

Clean Up Sites

Inspect the BGA for any missing pads, scratched solder mask

or any open connections that violate minimum electrical distance

2. Place

preform ball side up on flat surface.

Solder Preform Ball Side Up

3. Apply paste flux (water soluable preferred) to solder balls.

Apply Paste Flux to Solder Ball Side of preform

4. Align and place BGA onto preform

Align and Place Preform

5. Put “sandwich” through the reflow process

6. Peel apart preform

7. Clean with water

8. Inspect

The process for reballing a single BGA once you

get good at it is 5 or so minutes of labor assuming that no rework is

performed. Once you get some proficiency at this process you should be yield

85% or better. The BEST BGA Reballing kit is your answer to your fast

turnaround BGA reballing challenges.