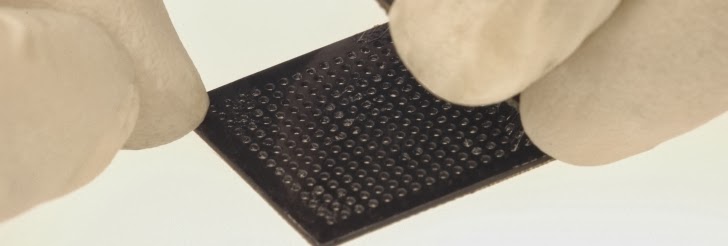

The epoxy found in the BEST PCB epoxy repair kit

has been proven useful for many different kinds of repair. It’s main use if for

adhering or re-adhering pads and traces onto PCBs when they are lifted or need

to be replaced. In addition, the epoxy has found use in the repair of damaged

corners or repairing burnt out areas of the laminate as filler. By adding the

proper colorant and by creating a “skim coat” for the outside surface of the

repair, the PCB epoxy can be an effective replacement. Another use of the PCB epoxy is for mask replacement. Here again a little colorant plus the

properly mixed epoxy will repair damaged solder mask areas.

|

| Green Colorant for PCB repair |

The PCB

epoxy comes convenient packed and premixed. Simply “burst” the barrier between

the resin and hardner and mix it by moving it along the hard edge until it

looks consistent.

Cut the tip

off the bag and you can begin applying the epoxy.

|

| PCB Repair Epoxy Resin and Hardner |

Not only is

this a versatile product but it has been a proven, reliable and effective

material for 20 plus years having been used on tens of thousands of PCBs. There

are a few published reliability and efficacy studies. There are many more

company confidential studies that have been generated to prove the material is

being effective in their end user environment including in leading cell phone,

IT infrastructure and medical products.

.jpg)